What is Cold Laminating Film for Advertising Materials?

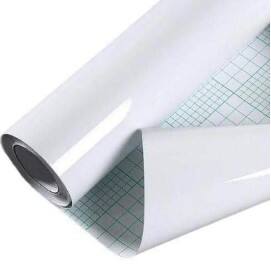

Core Composition & Structure

Cold laminating film is a specialized material designed for protection and enhancement of printed items. Typically, it consists of a clear polyester base coated with a pressure-sensitive adhesive, allowing easy application without the need for heat. The multi-layer structure of the film is crucial, as it helps shield printed materials from scratches, moisture, UV light, and other environmental factors, ensuring longevity and durability. Furthermore, understanding the importance of material quality is vital, with thickness options measured in microns catering to diverse advertising needs. Selecting the appropriate thickness can provide added protection while maintaining visual appeal, making cold laminating film indispensable for advertising materials.

How Pressure-Sensitive Adhesive Works

Pressure-sensitive adhesives (PSAs) are integral to cold laminating films, providing strong adhesion without requiring heat activation. Upon application, these adhesives bond to surfaces through mere pressure, exhibiting unique tackiness and characteristics that determine their effectiveness. PSAs are particularly valued in advertising as they support easy removal and repositioning, vital for versatile marketing applications. The adhesive technology not only simplifies the application process but also enhances the adaptability of advertising materials, enabling adjustments as needed without compromising the quality or appearance of the prints.

Key Benefits of Using Cold Laminating Film

Weather Resistance for Outdoor Durability

Cold laminating film is renowned for its robust weather resistance, which is vital for outdoor advertising materials. This film safeguards against moisture, UV rays, and varying weather conditions, thereby enhancing the lifespan of printed advertisements that are exposed to outdoor environments. Industry standards and studies have demonstrated the film's efficacy in enduring harsh conditions, such as fluctuating temperatures and direct sunlight, without compromising the quality of the print. An example of this is seen in long-term outdoor advertising campaigns, where cold lamination has been pivotal in maintaining the integrity and vibrancy of visual displays, ensuring that they remain eye-catching and effective over time. This durability not only provides an economic advantage by reducing the need for frequent replacements but also contributes to sustainable advertising practices.

Enhancing Color Vibrancy with Glossy/Matt Finishes

The choice between glossy and matte finishes in cold laminating films plays a significant role in influencing the visual appeal of advertising materials. Glossy finishes are known for their ability to enhance color vibrancy and depth, making images pop with intense, bright colors, which is crucial for grabbing consumer attention. On the other hand, matte finishes offer a non-reflective surface that can convey sophistication and subtlety, allowing for clearer text readability. Industry research shows that the lamination process not only protects prints but also affects color reproduction and contrast, with specific finishes strategically used to align with brand aesthetics. For instance, a luxury car brand might choose a matte finish to emphasize exclusivity, while a tech company might opt for a glossy finish to highlight innovation and modernity. This strategic use of finishes helps in effectively conveying brand messages through enhanced aesthetics.

Compatibility with Inkjet Printable Vinyl

When it comes to digital printing applications, the compatibility of cold laminating film with inkjet printable vinyl is crucial. This pairing ensures that the vinyl adheres properly while benefiting from the protective qualities of lamination. Selecting the appropriate cold laminating film is essential to achieve optimal adhesion without compromising the quality of the printed image. Successful case studies highlight how brands have achieved outstanding results by matching inks and lamination techniques effectively. These partnerships have allowed companies to produce high-quality, durable graphics that meet client expectations and withstand various environmental conditions. This compatibility not only maximizes the protective attributes of the lamination but also extends the functional longevity of the printed material, which is a significant advantage in high-stakes advertising and promotional environments.

Applications in Modern Advertising

Vehicle Wraps & Car Stickers

Cold laminating films offer remarkable benefits for vehicle graphics by providing essential protection against UV rays and enhancing durability against scratches and fading. This ensures that the vivid and intricate designs on vehicle wraps remain vibrant over time. Such laminating films significantly boost brand visibility, as vehicles become moving billboards, drawing attention wherever they go. Statistics have shown that vehicle wraps can increase brand awareness by up to 15 times compared to static advertising methods. Furthermore, with urban marketing strategies pivoting towards personalized and direct ad placements, car wraps have emerged as a trendy and effective form of advertising, offering businesses a high return on investment.

UV-Protected Outdoor Signage

Cold laminating films play a pivotal role in increasing the lifespan of outdoor signage, especially in areas with intense sunlight exposure. The UV protection offered by these films ensures that the colors and clarity of the signage remain intact for extended periods. According to research, UV-protected signs last up to twice as long as their untreated counterparts, reducing replacement and maintenance costs. Several businesses have reported improved brand visibility and prolonged outdoor advertising campaigns by employing UV-protected cold lamination. These real-world examples highlight the importance of investing in quality laminating films for outdoor marketing efforts.

Retail Displays & POP Graphics

In the competitive retail environment, eye-catching and durable displays are crucial for capturing consumer interest. Cold lamination is key to achieving high-quality Point of Purchase (POP) graphics, offering a protective layer that maintains the appearance of displays. Laminated materials are known to increase sales performance by preserving the visual attractiveness of promotional materials under frequent handling. Brands utilizing cold laminating film in their retail strategies often report a noticeable increase in sales, as their displays continue to look pristine regardless of the environmental challenges. This underscores the effectiveness of laminating films in diverse retail settings.

Choosing the Right Cold Laminating Film

Thickness Guide: 70-100 Micron Options

Selecting the appropriate thickness of cold laminating film is crucial for advertisers aiming for durability and rigidity in their applications. The 70 to 100 micron range is generally considered optimal, as it balances robustness and flexibility, making it suitable for various advertising contexts. Heavier films, while more durable, may also be less flexible, which can impact usability in certain environments. Print professionals often recommend using thicker films for outdoor applications, where increased protection from the elements is necessary. Expert opinions suggest taking the specific needs of your application into account and choosing a thickness that aligns with your goals — whether it's greater resilience or ease of use in handling.

Permanent vs. Removable Adhesive Vinyl

Understanding the distinction between permanent and removable adhesive vinyls is essential for effective advertising deployment. Permanent vinyl offers long-lasting adhesion and is ideal for applications that require durability, like outdoor signage that faces harsh weather conditions. On the other hand, removable vinyl is perfect for temporary displays or campaigns needing easy removal without residue. This flexibility makes it suitable for seasonal promotions or events. Seasoned marketers emphasize considering the local environment and intended duration when selecting adhesives, ensuring that the choice aligns with the campaign's objectives and medium.

Matching Films to Printer Types (Solvent/UV/Aqueous)

Compatibility between cold laminating films and printer types such as solvent, UV, and aqueous is pivotal to achieving optimum print quality. Each printer type interacts differently with films: solvent printers work well with robust films, UV printers excel with UV-resistant coatings, and aqueous printers require softer films for smooth application. Guiding the choice of laminating film based on the specific printer and ink used ensures the highest quality results. Case studies have shown successful applications when the setups were precisely matched, leading to enhanced print clarity and longevity of the graphics. This tailored matching ensures that prints remain vibrant and resistant to environmental influences over time.

Installation & Maintenance Best Practices

Avoiding Bubbles & Delamination

A smooth application of cold laminating film requires careful attention to prevent bubbles and delamination, which are common installation errors. These issues can be avoided by employing proper techniques and using the right tools. One effective method is to start applying the film from the center and work your way outward, using a squeegee to eliminate any trapped air pockets. This approach ensures even pressure across the surface, reducing the chances of creating bubbles. Additionally, experts recommend using high-quality tools like seamless rollers for a professional finish, as they provide optimal results in achieving a bubble-free installation.

Temperature Considerations for Winter Applications

Temperature plays a crucial role in the installation and curing process of cold laminating films, particularly during winter. Colder climates can affect the adhesive properties and overall performance of the film. It is advised to apply laminating films within the recommended temperature range of 10°C to 30°C to ensure proper bonding and longevity. Temperature fluctuations can lead to changes in material properties, potentially reducing the effectiveness and lifespan of the adhesive. Maintaining a stable temperature during both application and storage can help in preserving the integrity of the laminate, ultimately benefiting its performance and durability.

Cleaning Laminated Surfaces Safely

Maintaining laminated surfaces involves careful cleaning to preserve their appearance and functionality. It is important to use non-abrasive cleaning solutions to prevent damage to the laminate's surface. Gentle cleaning techniques, such as using a soft cloth or sponge with a mild detergent, are recommended to avoid scratching or dulling the laminate. Regular maintenance not only keeps laminated surfaces aesthetically pleasing but also extends their lifespan. Experts emphasize using appropriate cleaning agents and avoiding harsh chemicals as they can compromise the adhesive or film quality over time. Following these guidelines ensures the laminated surfaces remain intact and visually appealing.

Cold Lamination vs. Alternative Solutions

Comparing Heat Lamination Equipment Requirements

When considering lamination methods, the equipment requirements for heat lamination differ significantly from those for cold lamination. Heat lamination demands specialized machines that use heat to activate the adhesive, often resulting in higher initial costs and operational expenses. In contrast, cold lamination equipment is simpler and typically more affordable as it uses pressure rather than heat, offering efficiency and ease of use. Many professionals in the print industry prefer cold lamination for jobs that require quick application without the need for extensive machinery. Testimonies from print experts highlight cold lamination's simplicity and cost-saving benefits, making it a favored choice for small to medium businesses.

Cost Efficiency Over Printable Adhesive Vinyl

Cold laminating film is not only effective but also cost-efficient compared to printable adhesive vinyl. By reducing the need for frequent replacements and minimizing maintenance costs, businesses can make substantial savings over time. Market trends have shown a steady growth in the preference for laminated solutions, which deliver enhanced durability and protection at a lower long-term cost. Recent research has demonstrated that companies adopting cold lamination technologies benefit from budget savings in their advertising campaigns, appreciating these investments’ longevity and robustness compared to alternative solutions like inkjet printable vinyl.

Longevity Against Environmental Stressors

Cold lamination stands out in terms of durability and resilience against environmental stressors, such as moisture, heat, and UV radiation, compared to other alternatives like permanent vinyl adhesive solutions. Expert observations and durability tests affirm that cold laminated materials have a longer lifespan and provide superior protection under adverse conditions. Businesses aiming to bolster their advertising strategies against environmental challenges can rely on cold lamination for its proven ability to safeguard prints in varied settings. Such resilience not only enhances longevity but also spells effective utilization of resources, making it a powerful tool for environmental resilience in business applications.

Frequently Asked Questions (FAQ)

What is a cold laminating film?

A cold laminating film is a clear polyester film coated with a pressure-sensitive adhesive, designed to protect and enhance printed materials without the need for heat activation.

How does cold laminating film protect outdoor advertisements?

Cold laminating film shields advertisements from scratches, moisture, UV light, and environmental factors, enhancing their durability and lifespan, especially in outdoor settings.

What finishes are available for cold laminating films?

Cold laminating films are available in glossy and matte finishes. Glossy finishes enhance color vibrancy, while matte finishes offer a non-reflective surface for sophisticated visuals.

Why is compatibility with inkjet printable vinyl important?

Compatibility ensures that the vinyl adheres properly to the laminate, maximizing protective qualities and extending the print's functional longevity.

What is the recommended thickness for cold laminating films?

The 70-100 micron range is optimal for balancing robustness and flexibility, catering to diverse advertising applications.

Should I choose permanent or removable adhesive vinyl for my campaign?

Permanent vinyl is ideal for long-lasting applications, while removable vinyl suits temporary setups needing easy removal without residue.

What are the temperature guidelines for applying cold laminating film in winter?

Cold laminating films should be applied within 10°C to 30°C to ensure proper adhesion and film performance, particularly in colder climates.

Table of Contents

- What is Cold Laminating Film for Advertising Materials?

- Key Benefits of Using Cold Laminating Film

- Applications in Modern Advertising

- Choosing the Right Cold Laminating Film

- Installation & Maintenance Best Practices

- Cold Lamination vs. Alternative Solutions

-

Frequently Asked Questions (FAQ)

- What is a cold laminating film?

- How does cold laminating film protect outdoor advertisements?

- What finishes are available for cold laminating films?

- Why is compatibility with inkjet printable vinyl important?

- What is the recommended thickness for cold laminating films?

- Should I choose permanent or removable adhesive vinyl for my campaign?

- What are the temperature guidelines for applying cold laminating film in winter?