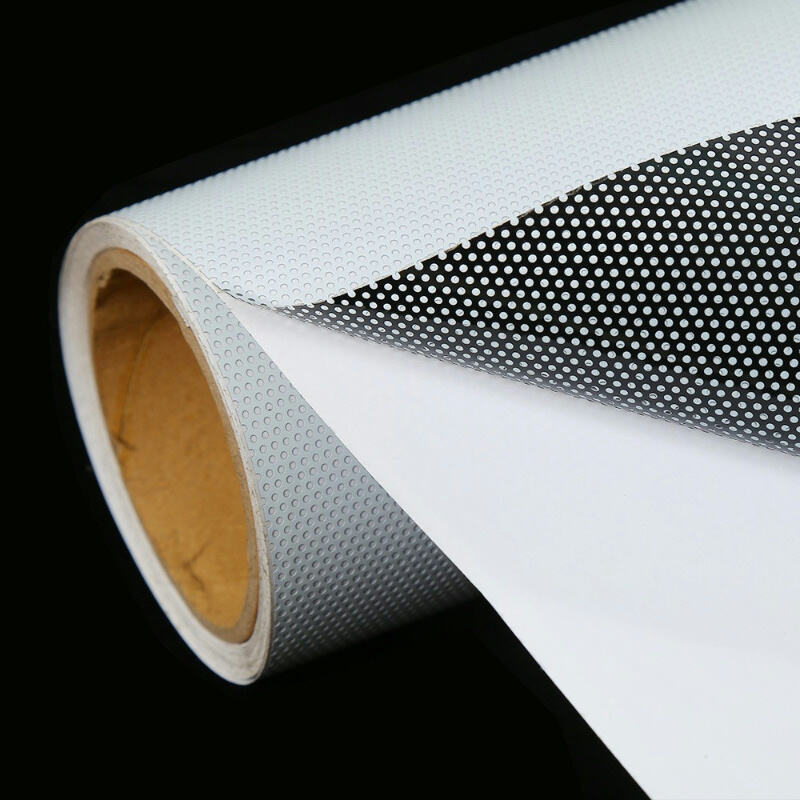

Perekat diri yang dapat dilepas dengan basis asetil menawarkan solusi unik untuk kebutuhan pengikatan sementara. Anda akan menemukannya digunakan di industri seperti pengemasan, pelabelan, dan kerajinan karena kinerjanya yang dapat diandalkan dan kemudahan dalam pelepasan. Ketika Anda memilih perekat diri yang dapat dilepas, memilih perekat yang tepat sangat penting. Ini memastikan kompatibilitas dengan permukaan, meningkatkan daya tahan, dan memenuhi tuntutan aplikasi tertentu. Tanpa pemilihan yang tepat, Anda berisiko mengalami daya rekat yang buruk atau sisa yang tertinggal. Dengan memahami perekat ini, Anda dapat membuat keputusan yang tepat yang menghemat waktu dan usaha sambil mencapai hasil terbaik.

Faktor Kunci yang Perlu Dipertimbangkan Saat Anda Memilih Perekat Diri yang Dapat Dilepas

Memilih perekat diri yang dapat dilepas yang tepat bisa terasa membingungkan, tetapi dengan fokus pada beberapa faktor kunci, prosesnya menjadi jauh lebih mudah. Mari kita uraikan agar Anda dapat membuat keputusan terbaik untuk kebutuhan Anda.

Kompatibilitas dengan Permukaan dan Material

Hal pertama yang harus Anda periksa adalah apakah perekat bekerja dengan baik pada permukaan yang Anda aplikasikan. Bahan yang berbeda, seperti kaca, plastik, atau logam, bereaksi berbeda terhadap perekat. Beberapa permukaan mungkin halus, sementara yang lain memiliki tekstur. Perbedaan ini mempengaruhi seberapa baik perekat menempel dan seberapa mudah dapat dihapus.

Misalnya, jika Anda bekerja dengan permukaan yang sensitif seperti dinding yang dicat, Anda akan menginginkan perekat yang dapat dihapus dengan bersih tanpa mengelupas cat. Di sisi lain, permukaan kasar mungkin memerlukan daya rekat yang lebih kuat agar tetap di tempat. Selalu uji perekat pada area kecil terlebih dahulu untuk menghindari kejutan.

Ketahanan dan Kinerja Lingkungan

Ketahanan itu penting, terutama jika perekat akan menghadapi kondisi yang menantang. Pikirkan tentang di mana dan bagaimana Anda akan menggunakannya. Apakah akan terpapar panas, dingin, atau kelembapan? Beberapa perekat bekerja lebih baik pada suhu ekstrem, sementara yang lain mungkin kehilangan daya rekatnya.

Faktor lingkungan seperti kelembapan atau paparan bahan kimia juga dapat mempengaruhi kinerja. Misalnya, perekat yang digunakan di luar ruangan perlu tahan terhadap hujan dan sinar UV. Jika Anda menggunakan perekat di area dengan kelembapan tinggi, seperti kamar mandi, pastikan itu tidak akan melemah seiring waktu. Memeriksa spesifikasi produk membantu Anda memahami bagaimana ia akan bertahan di lingkungan spesifik Anda.

Persyaratan Khusus Aplikasi

Setiap proyek memiliki kebutuhan unik, jadi penting untuk mencocokkan perekat dengan aplikasi Anda. Apakah Anda menggunakannya untuk label sementara, kerajinan, atau tujuan industri? Setiap kasus penggunaan menuntut sifat perekat yang berbeda.

Untuk aplikasi sementara, Anda akan menginginkan perekat yang mudah dihapus tanpa meninggalkan residu. Sebaliknya, penggunaan industri mungkin memerlukan daya rekat yang lebih kuat dengan kemampuan untuk dihapus secara tepat. Juga, pertimbangkan metode aplikasi. Beberapa perekat bersifat sensitif terhadap tekanan, sementara yang lain mungkin memerlukan aktivasi panas atau air. Mengetahui detail ini memastikan Anda memilih perekat self-adhesive yang dapat dihapus yang cocok untuk proyek Anda dengan sempurna.

Dengan fokus pada faktor-faktor ini—kompatibilitas, daya tahan, dan kebutuhan spesifik aplikasi—Anda dapat dengan percaya diri memilih perekat self-adhesive yang dapat dihapus yang memberikan hasil yang Anda cari.

Jenis-Jenis Perekat Self-Adhesive yang Dapat Dihapus dengan Basis Asetil

Ketika Anda memilih perekat self-adhesive yang dapat dihapus, memahami berbagai jenis yang tersedia dapat membantu Anda membuat keputusan terbaik untuk proyek Anda. Setiap jenis menawarkan sifat unik yang sesuai untuk aplikasi tertentu. Mari kita jelajahi tiga jenis utama perekat self-adhesive yang dapat dihapus dengan basis asetil.

Perekat Sensitif Tekanan (PSA)

Perekat sensitif tekanan (PSA) adalah salah satu pilihan yang paling serbaguna. Perekat ini menempel pada permukaan ketika Anda menerapkan tekanan ringan. Anda tidak memerlukan panas, air, atau metode aktivasi tambahan. Ini membuatnya sangat nyaman untuk aplikasi yang cepat dan mudah.

PSA bekerja dengan baik untuk label sementara, stiker, dan tanda. Mereka menempel pada berbagai permukaan, termasuk kaca, plastik, dan logam. Anda akan menemukan mereka sangat berguna ketika Anda memerlukan penghapusan bersih tanpa meninggalkan residu. Namun, kinerjanya dapat bervariasi berdasarkan faktor lingkungan seperti suhu dan kelembapan. Selalu periksa spesifikasi produk untuk memastikan mereka memenuhi kebutuhan Anda.

Perekat yang Diaktifkan oleh Panas

Perekat yang diaktifkan oleh panas memerlukan panas untuk menempel pada permukaan. Perekat ini ideal untuk aplikasi di mana Anda memerlukan ikatan yang lebih kuat dan lebih tahan lama. Anda sering melihatnya digunakan di lingkungan industri atau untuk proyek yang membutuhkan presisi.

Untuk menggunakan perekat yang diaktifkan oleh panas, Anda memerlukan sumber panas, seperti pistol panas atau peralatan khusus. Setelah dipanaskan, perekat menjadi lengket dan menempel dengan aman pada permukaan. Jenis perekat ini sempurna untuk bahan yang perlu tahan terhadap suhu tinggi atau kondisi yang menantang. Perlu diingat bahwa proses aplikasi mungkin memerlukan lebih banyak waktu dibandingkan dengan perekat yang sensitif terhadap tekanan.

Perekat Berbasis Air

Perekat berbasis air menawarkan opsi ramah lingkungan bagi mereka yang memprioritaskan keberlanjutan. Perekat ini diaktifkan saat terpapar air, menjadikannya pilihan yang sangat baik untuk aplikasi di mana dampak lingkungan penting.

Anda akan menemukan perekat berbasis air yang umum digunakan dalam kerajinan, pengemasan, dan aplikasi ringan lainnya. Mereka memberikan ikatan yang dapat diandalkan sambil tetap mudah untuk dihapus. Namun, mereka mungkin tidak berkinerja baik di lingkungan dengan kelembapan tinggi atau dalam kondisi ekstrem. Jika Anda mempertimbangkan jenis ini, uji di pengaturan spesifik Anda untuk memastikan itu memenuhi harapan Anda.

Dengan memahami ketiga jenis ini—sensitif terhadap tekanan, diaktifkan oleh panas, dan berbasis air—Anda dapat memilih perekat diri yang dapat dilepas yang sesuai dengan kebutuhan proyek Anda. Setiap jenis memiliki kekuatannya masing-masing, jadi mengetahui apa yang Anda butuhkan akan membimbing Anda menuju solusi yang tepat.

Panduan Langkah-demi-Langkah untuk Mengevaluasi dan Menguji Perekat

Ketika Anda memilih perekat diri yang dapat dilepas, mengevaluasi dan mengujinya memastikan Anda mendapatkan produk yang tepat untuk kebutuhan Anda. Panduan langkah-demi-langkah ini akan membantu Anda membuat keputusan yang percaya diri dan menghindari kesalahan yang mahal.

Mengidentifikasi Kebutuhan Spesifik Anda

Mulailah dengan memahami apa yang Anda butuhkan dari perekat. Tanyakan pada diri sendiri beberapa pertanyaan kunci:

Jenis permukaan apa yang akan Anda aplikasikan? Permukaan halus seperti kaca atau yang memiliki tekstur seperti kayu mungkin memerlukan perekat yang berbeda.

Berapa lama Anda membutuhkannya untuk tetap di tempat? Aplikasi sementara mungkin memerlukan kemudahan untuk dilepas, sementara penggunaan jangka panjang mungkin membutuhkan daya rekat yang lebih kuat.

Apakah itu akan menghadapi tantangan lingkungan? Pertimbangkan faktor-faktor seperti suhu, kelembapan, atau paparan terhadap bahan kimia.

Catat persyaratan ini. Memiliki daftar yang jelas membantu Anda mempersempit pilihan dan fokus pada perekat yang memenuhi kriteria Anda. Misalnya, jika Anda sedang mengerjakan proyek di lingkungan yang lembap, Anda akan menginginkan perekat yang berkinerja baik dalam kondisi tersebut.

Menguji Kinerja Perekat

Setelah Anda mengidentifikasi kebutuhan Anda, saatnya untuk menguji perekat. Pengujian memastikan bahwa ia berfungsi seperti yang diharapkan dan menghindari kejutan di kemudian hari. Ikuti langkah-langkah ini:

Terapkan Sampel Kecil: Gunakan sepotong kecil perekat pada permukaan yang dimaksud. Ini memungkinkan Anda melihat seberapa baik ia menempel dan dapat dihapus tanpa terikat pada seluruh proyek.

Periksa Kekuatan Perekat: Tekan perlahan perekat ke permukaan. Apakah ia menempel dengan aman? Jika terasa lemah atau terlalu kuat, mungkin itu bukan pilihan yang tepat.

Uji Kemudahan Penghapusan: Lepaskan setelah beberapa jam atau hari. Periksa sisa atau kerusakan pada permukaan. Perekat yang baik seharusnya tidak meninggalkan jejak.

Simulasikan Kondisi Lingkungan: Paparkan perekat pada panas, dingin, atau kelembapan jika proyek Anda melibatkan kondisi tersebut. Langkah ini memastikan ia berfungsi dengan baik dalam skenario dunia nyata.

Pengujian memerlukan sedikit waktu, tetapi ini menyelamatkan Anda dari potensi masalah. Lebih baik menemukan masalah selama pengujian daripada selama proyek Anda yang sebenarnya.

Konsultasi Pedoman Pabrikan

Pabrikan memberikan informasi berharga tentang produk mereka Produk Selalu tinjau pedoman dan spesifikasi sebelum membuat keputusan akhir. Dokumen-dokumen ini sering kali mencakup:

Permukaan dan bahan yang direkomendasikan untuk perekat.

Rentang suhu untuk kinerja optimal.

Instruksi untuk aplikasi dan penghapusan.

Jika Anda tidak yakin tentang sesuatu, jangan ragu untuk menghubungi produsen. Mereka dapat menawarkan saran ahli dan menjelaskan keraguan apa pun. Langkah ini sangat penting untuk proyek yang kompleks atau berisiko tinggi di mana presisi sangat penting.

Dengan mengikuti langkah-langkah ini—mengidentifikasi kebutuhan Anda, menguji kinerja, dan berkonsultasi dengan pedoman—Anda akan merasa percaya diri dengan pilihan Anda. Mengambil waktu untuk mengevaluasi dan menguji memastikan Anda memilih perekat self-adhesive yang dapat dilepas yang bekerja dengan sempurna untuk proyek Anda.

Memilih perekat self-adhesive yang dapat dilepas dengan basis asetil yang tepat memerlukan pertimbangan yang cermat. Anda perlu memahami bagaimana kompatibilitas, daya tahan, dan kebutuhan spesifik aplikasi mempengaruhi kinerja. Menguji perekat sebelum berkomitmen memastikan Anda menghindari masalah seperti daya rekat yang buruk atau sisa. Selalu luangkan waktu untuk mengevaluasi produk dalam kondisi dunia nyata.

"Jika ragu, konsultasikan dokumentasi produk atau hubungi ahli untuk mendapatkan saran."

Langkah sederhana ini dapat menghemat waktu dan usaha Anda. Dengan mengikuti tips ini, Anda akan membuat pilihan yang percaya diri dan mencapai hasil terbaik untuk proyek Anda.